Zero liquid discharge (ZLD) is an engineering approach to water treatment where all water is recovered and contaminants are reduced to solid waste. While many water treatment processes attempt to maximize the recovery of freshwater and minimize waste, ZLD is the most demanding target because the cost and challenges of recovery increase as the wastewater gets more concentrated.

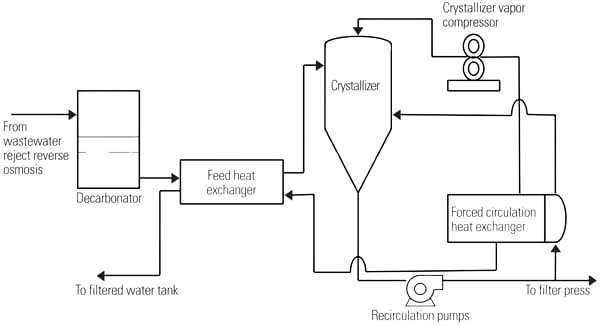

Salinity, scaling compounds, and organics all increase in concentration, which add costs associated with managing these increases. ZLD is achieved by stringing together water treatment technology that can treat wastewater as the contaminants are concentrated. The primary objective of ZLD is to minimize environmental impact by preventing any discharge of effluent into water bodies, thereby conserving water resources and reducing pollution.

Several methods of waste management are classified as ZLD, despite using different boundaries to define the point where discharge occurs. Usually, a facility or site property line that houses the industrial process is considered the border or boundary condition where wastewater must be treated, recycled, and converted to solids for disposal to achieve zero liquid discharge. Certain facilities send their liquid waste off-site for treatment, deep well disposal, or incineration and they consider this to qualify as ZLD.

Lower waste volumes decrease the cost associated with waste management.

Lower waste volumes decrease the cost associated with waste management. Recycling water on-site lowers water acquisition costs and risk. Recycling on-site can also result in fewer treatment needs, versus treating to meet stringent environmental discharge standards.

Recycling water on-site lowers water acquisition costs and risk. Recycling on-site can also result in fewer treatment needs, versus treating to meet stringent environmental discharge standards. Reduce trucks associated with off-site wastewater disposal and their associated greenhouse gas impact and community road incident risk.

Reduce trucks associated with off-site wastewater disposal and their associated greenhouse gas impact and community road incident risk. Improve environmental performance and regulatory risk profile for future permitting.

Improve environmental performance and regulatory risk profile for future permitting. Some processes may recover valuable resources, for example, ammonium sulfate fertilizer or sodium chloride salt for ice melting.

Some processes may recover valuable resources, for example, ammonium sulfate fertilizer or sodium chloride salt for ice melting.